Universal DRSSTC Tesla Coil Driver 2.7 Rev C

The

Universal DRSSTC Driver 2.7 Rev B (Oct 2014) - UD2.7C is the newest

revision.

Here is my take on Steve Ward's Universal DRSSTC Driver 2 which I have

named UD2.7. The UD2 is THE benchmark DRSSTC

Tesla Coil

driver: it has stood the test of time and been used in

thousands of high performance coils around the world. I came across Steve's original UD2 a while

back ago, but there were several new features I wanted to

incorporate. To be very clear, the original UD2 and essentially all of

its design must be credited to Steve Ward - without him there would not

be a UD2! In

addition, I thought it would also be a good idea to share a little bit

about how the UD2 works and how to get one working, with the Tesla Coil

community (with Steve's permission and generosity). Hopefully this

will be a useful resource to hobbyists around the world. The UD2.7 (now in

revision C) has since been

used successfully in a variety of coils, ranging from small table top

400kHz DRSSTCs, 35kHz large DRSSTCs with a full bridge of CM600 IGBTs

and even QCW operation (see application notes below).

This project will not be possible without the work of many people in the

high voltage community. Many thanks to Steve Ward for his generosity in

sharing the UD2 with the Tesla Coil community, and for his permission

for the modification and publication of this new version of the

Universal Driver. The UD2.7 is free for download for personal hobby use;

credit and all rights of the UD2 design goes to Steve Ward. Also, credit

goes to the many improvements made by Bart and Eric in the earlier V2.1

and V2.5 revision, which added many useful features.

At the moment I'm quite happy with the UD2.7C revision, and any new

features will probably be incorporated in a completely new driver design

I am working on for the future. Feel free to drop me a note if you've

successfully used this in your project or if you have any

suggestions or comments!

Quick Links

History and Overview

Theory of Operation

Schematic

Testing and Debugging

Tuning Phase Lead

Setting Over Current Detection

QCW Operation

Downloads

Latest Version V2.7 Rev C (as of Jan 2015)

- Schematic Rev C .png

and board layout .png

- Gerber Files of Rev C ready for production .zip

- Bill of Materials (V2.7 Rev C) .pdf

- Populated Mouser Project

Order

Previous Version V2.7 Rev A/B (not recommended any more)

- Schematic

.png

or .pdf

or .sch

and board .brd

... or UD2.7B schematic .png

- Gerber Files ready for production (V2.7 Rev A, 15

Sept 2014) .rar

See this

4hv forum thread for questions,

discussions and answers. This page will also

be continually updated.

If there are additional changes desired / comments / feedback,

please let me know for a future revision of the board.

Quick Notes

24VDC Input

- Small error in the UD2.7A and B design which has been fixed in the

UD2.7C; also does not apply if you are

only using the AC input jack. Otherwise, there is a simple fix if you are using the

24VDC input jack for the Rev A and B boards: solder on a general purpose diode across the

24V regulator from output to input (i.e. as a reverse protection

diode). See

below for more details.

C33 - C33 sets the dead time for the

TL3116 comparator hysteric feedback network for switching noise

immunity. The pads for the capacitor are increased in size for easy

changing of components. Good values range from

220pF to 2.2nF. For large IGBTs at low switching frequency (e.g.

CM600), use 2.2nF. For medium sized switches like CM200, 1nF

works well (change C33 to less than 1nF for operation above 200kHz). For

faster small IGBTs such as TO247 IGBTs at higher frequencies, use 220pF. Adjust C33 if noise

is found on the output of TL3116.

Fiber Units - The UD2.7 allows the

use of two different kinds of fiber optic input (the ST-type, and Industrial

Fiber Optics type). Use OPF-2412T or HFBR-2412T for ST fiber receivers,

& Industrial Fiber optics IFD95T or IFD95C (these are Active-High, be

careful that you do NOT buy the active low kinds). The fiber units are OR-ed together, so be sure to ONLY use one port for interrupter input to

avoid excessive pulse-widths. They can be installed individually by

themselves to save cost.

D13 - You can install both, only the

ST, or only the IF receiver to save cost. However, because the IF

receivers are active high, if you only install the ST receiver, you must

remove D13 to prevent the interrupter line

from not being pulled low.

Slot-7 Inductors - These 7M3-series

tunable inductors for phase lead adjustment can be bought or sampled

from www.coilcraft.com.

Inductance values varies depending on your switch and switching

frequency. Typical values include: 7M3-123 (9 - 15uH; works well with

TO247 IGBTs), 7M3-153 (11 to 19uH), going up through 7M3-223 (17-28uH),

333 (25-41uH), 393 (29-49uH; works well with CM200/300s), 563 (42 -

70uH) etc. Use a flat-head non-magnetic or plastic screwdriver for

tuning (see instructions below in this page).

Output Drive - UD2.7 has two identical

outputs for driving two bridges (via two GDTs), or can be paralleled to run a

single large

bridge (via one large GDT). To save BOM cost, the second gate drive section can be removed

during assembly -

anything after the phase jumper can be removed for the second circuit,

including the UCC FET drivers and the push-pull MOSFTs.

Feedback - I try to aim for about 1A

of feedback current; adjust your CT turns ratio appropriately. i.e.

if I'm expecting to run my bridge at 500Apk, I'll wind a 500:1 feedback

current transformer.

OCD Burden Resistor - The OCD burden

resistor (R17) is a single 5.1R 2W by default. For flexibility, an

second parallel space at R28 is provided for an optional secondary

resistor. The comparator voltage should ideally be less than 7V to keep

within the bounds of the comparator when on a 9V rail.

Setting OCD Current Limit / Phase lead -

See application notes below.

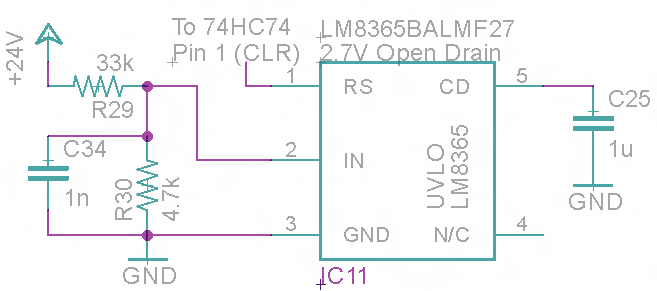

UVLO Setting (for UD2.7B onwards) - UVLO

trips when the voltage sense line drops below 2.7V (or 4.5V depending on

the part you use). This is set in

UD2.7A with a 33k/4.7k resistor divider across the 24V rail giving about 3V, for

the UVLO to trip when the 24V line drops to 21.65V or so. In

UD2.7B

onwards, R29

is a 50k pot which can be adjusted greater than 33k for a faster trip,

or a less than 33k for more leeway in 24V drop. Tap point 2 (TP2) is

conveniently located near R29 for easy voltage adjustment. This can be

set to 3.0V (or 5.0V for the 4.5V trip).

Note that the maximum voltage the LM8365 can tolerate is 6.5V.

By default, R29 (50k pot) comes set to half (25kR resistance). This

gives a safe voltage of around 3.8V by default which should be adjusted.

However, IF R29 is set to say 0R, this can place a very high voltage

(>6.5V) to the LM8365 causing it to pop! Be careful

when installing R29!

UD2.7 List of Improvements from UD2.0

Change List from UD2.0 to UD2.7A

- Heat-burning 9V regulator replaced with an

efficient switching

regulator (but still TO-220 compatible if you want, with space for heatsink!)

- All other regulators replaced with SMD ones, reducing overall height

of the board

- Added on-board SMD LED for power indication

- Under-voltage Lockout added for the 24V rail with threshold adjustment

- Flattened ground plane and some re-worked traces and component placing

- Added new 24VDC input jack for use with small DC power supply instead

of power transformer

- Improved solder pads for hard-to-solder components such as the dual

MOSFETs and some others

- Added series capacitor with 15R resistor in parallel with 2uF GDT

output capacitor to prevent burning out resistor in event of malfunction

- Improved silkscreen for easier use (e.g. LED breakout jack now labeled

on top)

- All through-hole resistors are now flat instead of standing up, for

increased robustness

- Some components changed to further reduce height of populated board

- Board edges rounded, mounting holes changed to circles, board size

shrunk to be even more compact

- Main component reference IDs (e.g. C33) maintained for easy discussion

on forums

- Includes all improvements from UD2.5 by Eric, such as added IF fiber optic input,

test point for OCD, and fixed errors

- Created BOM, documentation, and improved schematic

- New compact size - 2.4 x 3.7" footprint

More improvements for Rev B & Rev C

- Improved silkscreen and component placing

- Additional optional gate-drive capacitor pads add for use in high duty

cycle

applications with long pulse gate drive durations (optional)

- Added UVLO adjustment potentiometer for lock-out adjustment (or you

can use a resistor instead for a fixed one) and UVLO jumper

- Improved heat-sinking capabilities of 24V and 5V linear regulators

with less thermal relief on polygon pours

- Fixed error on 24VDC rail with now higher AC input range of 19-26.5VAC

nominal and 28VAC max

- Yet more improvements to silkscreen including diode direction labels

and other cosmetic improvements

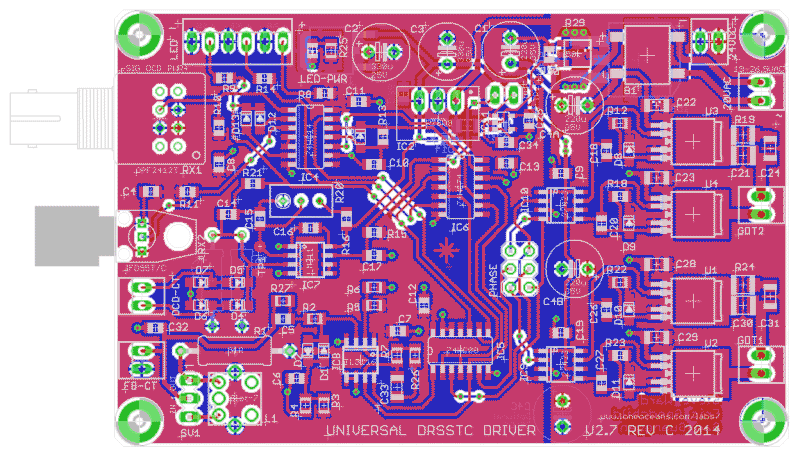

Board layout of UD2.7C showing top traces (red) and bottom (blue) with

silkscreen (white).

For more information / documentation , please read

below.

July 2014

History

What is the UD2? (summary)

The UD2 is a universal DRSSTC driver / controller board

originally designed by Steve Ward, and is an evolution of his UD1.3. The

UD2 accepts a fiber-optic interrupter input

and is capable of driving some large GDTs for DRSSTC operation with a

full or half bridge inverter. Its'

main feature is an adjustable phase-lead controller. It has had a proven

track-record in the field and has been used by many serious hobbyists around the

world.

UD1.3b

Steve Ward created the original Universal DRSSTC Driver

(referred to UD from now on) back in 2008, and was designed to be a

general purpose solution for most conventional DRSSTCs, yet powerful

enough to drive a large full bridge of transistors. It featured the

usual primary feedback circuit with a flip-flop, optical interrupter

input, over-current detection (OCD) as well as robust MOSFET driven

Gate Drive Transformer outputs. Version 1.3b was popularized on his

website and has been successfully used by many hobbyists around the

world.

UD2, 2.1, 2.5

In the quest for a better controller, Finn Hammer came

up with a clever idea of using Phase Lead in his driver; a feature which he called

'Prediktor'. In essence, a little bit of phase lead is added to the

input signal to the driver. The result is that the power transistors can

now be switched slightly earlier - this is desirable because large IGBTs have

a non-zero switching time, and switching earlier allows for perfect zero

voltage switching. Using this idea, Steve Ward

developed a newer controlled dubbed the UD2, adding adjustable lead

compensation via a variable inductor in a LC feedback network. Since

then, several improvements and fixed have been made to the UD2 such as the UD2.1B

by Phillip Slawinski and Bart Anderson, as well as a more recent

improvement the UD2.5 by Eric Goodchild; a shout-out to them for

their work! These improvements have

resulted in additional features such as small fixes, addition of an

additional fiber input, component placing, and other tweaks. Many thanks

and credits to these folks who have contributed back to the Tesla Coil

community.

However, there were still some problems left which I

really wanted to improve and use in my own projects, so I decided to do my

own revision on the UD2. I don't know what the naming convention is but I've

decided to call it UD2.7. I've built on the work

contributed

by the Tesla Coil community, but all rights are still reserved by Steve

Ward who originally created the UD2!

Some of the main problems I had with the UD2

were the linear voltage regulators, especially the 9V and

5V regulators which had a habit of getting very hot with reports

of them letting out their magic smoke due to heat/overvoltage. The

original UD2 placed the regulators in a very awkward position

which was difficult to heat-sink. This was addressed in UD2.5,

but I really wanted to do away with heat sinks for reliable

long-term enclosed operation. In addition, the

UD still did not have a Under-voltage Lockout, which I

think is essential. I also wanted to improve the hand-solderability

of the board, and make the board easier to use.

I made a list of improvements I wanted and

implemented them. The result is what I hope to be a more physically

robust board, as well as a driver that is more reliable for long-term operation in a

confined space.

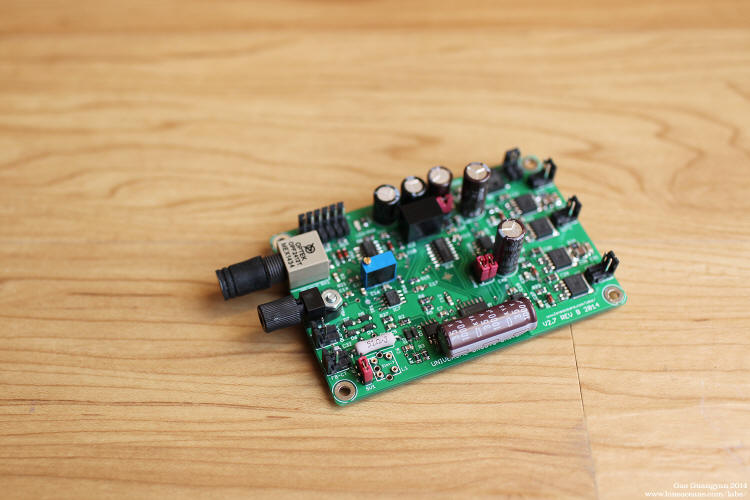

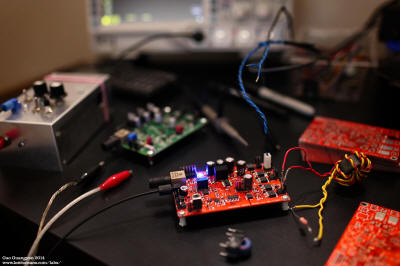

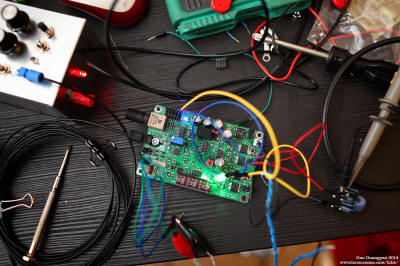

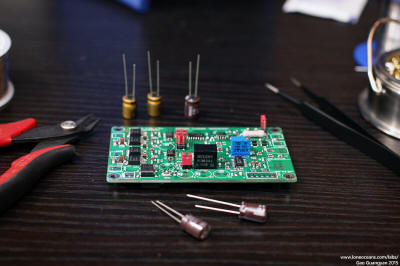

Photos of the UD2.7

These are some photos of the completed and assembled

board. These photos show the UD2.7A.

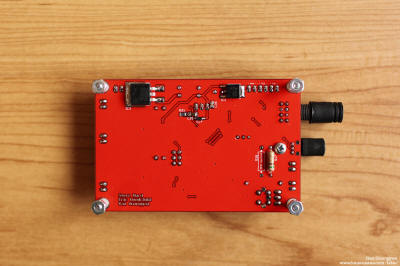

Notice that I've hidden some components at the bottom

of the board to maintain the general layout and to avoid changing the

size of the PCB.

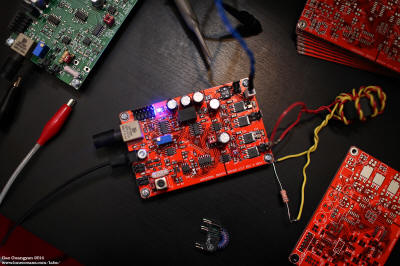

Above in green is a slight revision to the UD2.7A - the UD2.7B. It is essentially identical except for a few tweaks, and

has added space for an optional large drive capacitor (C4C), along with UVLO

adjustment.

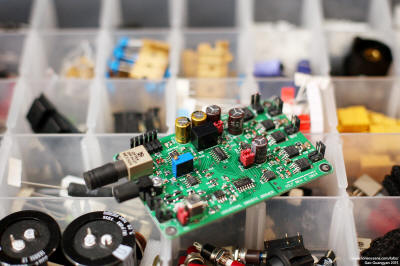

The latest revision is the UD2.7C, hopefully with final

modifications. Above shows a UD2.7C decked out with some shiny gold

capacitors!

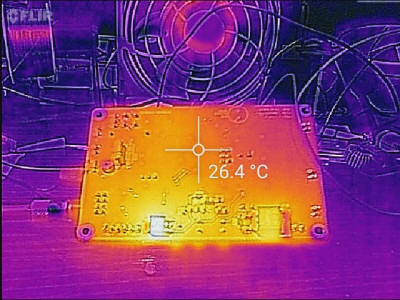

Thermal Analysis

As mentioned, one aspect of previous UDs were that the

linear regulators (especially the 9V one) got really hot. I wasn't keen

of the idea of heat-sinking, so I replaced the regulator with a

switching one, and mounted the other two (changed to the SMT variant) on

the bottom of the board. The large ground plane at the bottom of the

board acts as a heatsink for the regulators.

I used a FLIR thermal camera to see how warm these

components would get when fed with 20VAC, with an ambient temperature of

24C. After 5 minutes of idle time, the hottest parts of the

boards were still the regulators with the 9V switcher topping out around

33+C and the 5V regulator at about 32C. The bridge rectifier and the 3116 were also very slightly warm.

Regardless, a significant improvement over the previous boards which had

regulators that ran

closer to 70C! In typical use, the main regulators and switching FETs

will get a fair bit warmer but still run much cooler than the original

design

.

If you're tinkering with a UD2, you should already be quite

familiar with DRSSTC, have a solid understanding of basic EE, and should be able to figure out

how to read the schematic. I've seen many

beginners wanting to build their first DRSSTC with a UD2 without

prior EE experience. In my opinion, if you are new to DRSSTCs or

SSTCs, I'd highly recommend learning a little more by building a

simpler non-resonant SSTC first, before moving on to DRSSTCs and

the UD2 controller.

General Specifications for UD2.7C

Input - 19 to 26.5VAC recommended input, with

18-28VAC absolute limits. Alternatively, use a 24VDC

input (choose and use one of the appropriate input headers)

Frequency Range - Tested from 12kHz to 1MHz (C33

= 2.2nF from 12kHz to 240kHz, C33 = 220pF to 1nF for up to 1MHz)

Compatible IGBTs - Huge range - from small TO220

IGBTs / MOSFETs to a full bridge of CM600HA IGBTs

Gate Drive - Two push-pull +- 24V

Gate-drive-transformer drivers, can be wired in parallel for

driving larger bridges

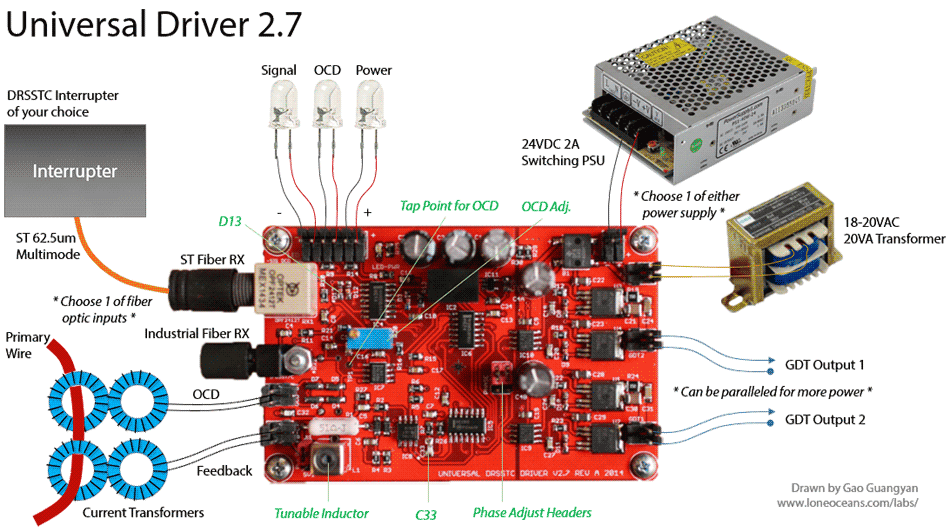

Wiring Diagram

The UD2.7 can be wired up as described in this quick set-up

diagram:

Some things to note include:

-

Ability to use either a

24V SMPS or a 18-20VAC transformer. A roughly 30VA power source

should be sufficient for most coils, but you should calculate

the total gate drive power required to be sure. Ensure that you

are plugging the power supply in the correct input jack as

labeled on the board since there is no reverse protection for the DC

input.

-

For CT feedback, I aim for about 1A of feedback;

wind your feedback current transformer to achieve this ratio.

-

OCD trip values work best around 2 to 7V to work

within the range of the comparator. This should dictate what turns

ratio you need for the OCD CT, when combined with the 5.1 ohm burden

resistor.

-

The GDT

outputs can be wired in parallel for driving a large bridge

of IGBTs such as CM600s.

-

Note that the above diagram is of the

UD2.7A. The B revision onwards includes an extra jumper for UVLO,

as well as a potentiometer for adjusting the UVLO set voltage (via

Tap point 2), and extra through-hole pads for C4C, for more 24V rail

capacitance if required.

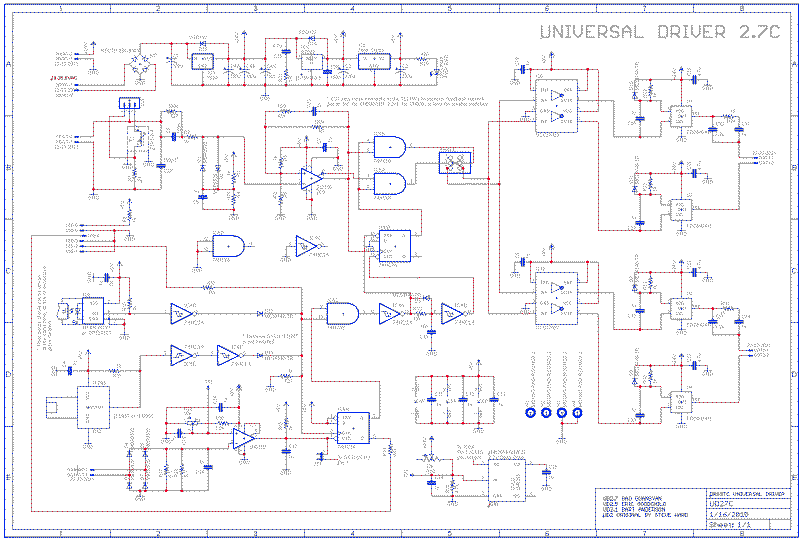

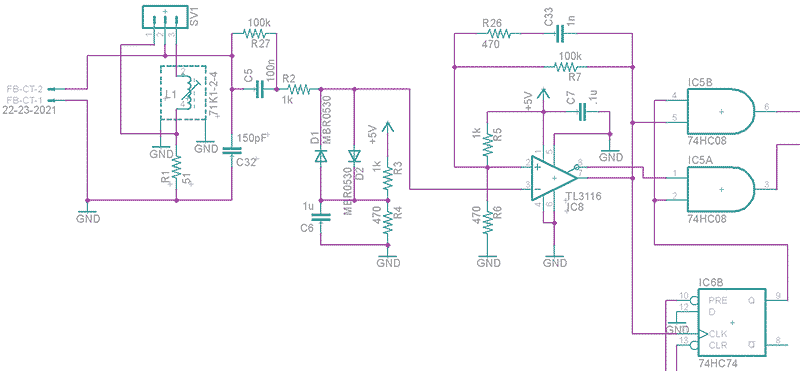

Here is the complete schematic for UD2.7 updated with my

modifications and presented with permission from Steve Ward.

UD 2.7C schematic - click to see in full

resolution.

Let us go through overall the different components of the

circuit. I won't go into them with too much detail, but if you

have any experience with electronics, you should easily be able

to figure out out all by yourself. For previous versions, note that the

Rev B has a few

tiny changes to Rev A.

If you find any mistakes that I have made, please let me

know! [Update - Errata found in the 24VDC input

jack with simple fix - see here

for more details! - this is fixed in Rev C where the 9V

regulator is now daisy-chained off the 24V regulator].

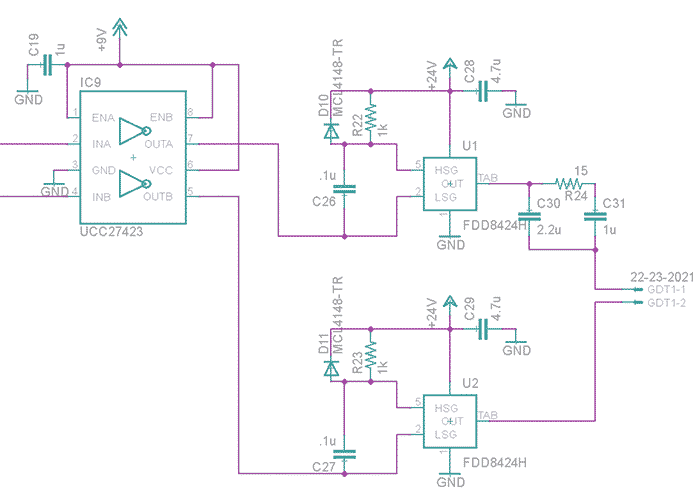

The Gate Driver

The gate drivers are straightforward and designed to drive Gate

Drive Transformers with 50% duty cycle. I have reproduced one of

the two identical gate drive blocks above for simplicity of

discussion.

Beginning from the left to right, the control signal comes in to

IN_A and IN_B of the

UCC

Inverting Mosfet drivers

(note that the UCCs here are always enabled, and they are dual

inverting). These input control signals come from the logic

section of the UD2, and IN_A is logically opposite of IN_B. You

would think that it is possible to drive a GDT direction from

the outputs of the UCC27423, and you would be right - the

UCC27423 is a dual 4A MOSFET driver, and they are capable of

driving a small GDT by itself, but we can add a complementary

MOSFET buffer on the output of this to beef up the gate drive

capability in both voltage and current.

Instead, the UCC27423 is used to drive the gates of pair of

complementary N/P FET pairs - these are two FDD8424H

40V 20A MOSFETs.

This output stage creates the +-24V signal to the GDT output.

Note that driving your IGBT gates at 24V is

over typical maximum operating characteristics of almost all

IGBTs! There are several reasons for over-driving the

gates though it is not a topic for discussion here. Suffice to

say it is possible to have a lower input on the 24V rail all the

way down to around 11-12VDC as long as it is sufficient for the

9V regulator's input. Adjust the UVLO accordingly if you are

changing the 24V rail voltage. Another alternative is to wind

your GDT with a less than 1:1 turns ratio.

Note that the schematic labeling is a bit confusing here - TAB

corresponds to D1 and D2 of the FET pair in the FDD8424H; S1 is

tied to GND, S2 (of the P Channel FET) is tied to 24V.

Output of the UCC begins as high (9V), turning on the N channel

FET and pulling the output (TAB) to GND. At this time, G2 (pin

5) is pulled by R22 to be 24V, so the P Channel FET is off. When

the UCC begins switching, OUTA/B goes to 0V, turning the N

channel FET off. The signal is capacitatively coupled via C26,

creating a square wave signal same as in the drive signal on pin

2 as pin 5, but shifted by 24V (so about 24V to 15V). The

FDD8424H pair here has a very low gate threshold V_gs voltage of

1.7/-1.6V N/P. This causes the N FET to go OFF, P to go ON,

causing TAB to swing to 24V. Likewise, this happens the same way

on the other pair, creating a 24V push-pull output for the GDT.

The diodes (D10/11) is necessary to clamp the P-FET gate to a

maximum of 24V. Otherwise during the 0V to 9V transition, the

P-gate will jump from 24 to 33V. D10/11 allows current to flow

through during the transitions in on direction, keeping the gate

to a 24-15V drive waveform.

Notice that the output from the push-pull pair is capacitatively coupled via the

DC-blocking capacitor C30, a

beefy high current capable 2.2uF MLCC capacitor. This is important as it prevents

'flux walking' on the GDT and eliminates any DC bias which can

lead to core saturation. R24 is a

15R resistor that damps ringing with the leakage inductance of

the GDT and circuit capacitance, which might accidently turn on

the IGBTs on the GDT secondary. To prevent burning out R24 in

the event of a malfunction (e.g. suppose the driver is stuck on

high and low on both sides for some reason, there will be 24V across the

resistor for a long time which could burn it out), C31 is added

as a DC blocker. This circuit is

duplicated twice for two outputs.

Feedback and notes on over-current setting

The UD2.7 is simply a current-sending feedback driver at its heart, and feedback

is usually obtained from the primary resonant circuit via a current

transformer. The UD2 adds phase lead functionality, where the

feedback signal is fed into a LR circuit, which adds some

lead-time into the feedback signal, adjustable by the inductance

of L1. We know that across an inductor, the current lags the

voltage (and opposite across a capacitor, where the voltage lags

the current). This is the way phase lead is introduced by the

inductor, where the feedback current is lagging the voltage

signal, and it is this voltage signal we are sending to the

fast TL3116 comparator.

There is some 'cleaning up' after the LR stage before the signal

arrives to the comparator, to square it up as much as possible.

The phase lead voltage signal is sinusoidal in nature, which can

lead to a variable output delay when fed into a comparator with

a wide hysteresis band. As a result, the phase lead circuit uses

a relatively high voltage across the LR filter (~50+V across the

51R at 1A), and then fed through a resistor into a diode clamp

circuit to make it into a reliable square signal. Note that during the beginning

cycles, the feedback voltage starts off

small, so the comparator needs to have a small hysteresis band

to avoid noisy switching, so that the delay between zero

crossing feedback and the comparator output change is small. The

high voltage minimizes this switch delay, especially during

startup.

The current in the CT matches the current in the primary

resonant circuit and is sinusoidal in shape. R3 and R4 together

with C6 acts as a resistor divider from a 5V rail to generate a

DC-offset of about 1.6V. R2 attenuates the signal which is

capacitively coupled via C5, to create a superimposed sinusoidal

feedback signal with a 1.6V voltage off-set. The two diodes D1

and D2 help to 'square up' the signal to form a more

square-shaped, AC signal centered around 1.6V with faster rise

and fall times. This is then fed into IC8, the fast comparator

with a compare reference voltage of 1.6 (formed by R5 and R6),

which places the comparator in its optimal operating range. Note that TL3116

can be replaced with a variety of fast pin-compatible

comparators.

In this way, the TL3116 acts as a zero current crossing detector.

After the comparator is a little bit of simple logic before

going to the gate drive block we discussed previously.

The two outputs of the comparator (inverted and non-inverted) go

into IC5 (AND gates), which then act as the logic signal for the

gate drive block.

The non-inverting output of the comparator also acts as a clock signal to the 74HC74 D Flip flop.

The output of the flip-flop (Q) must be logic 1 for both the AND

gates to send an output to the gate driver. The flip flop therefore

acts as the control to turn on and off the drive, and this can

be achieved by forcing Q to go high or low. We will see how the

interrupter input turns on the drive signal, and this can be

stopped by OCD, end of drive, or UVLO, all synchronized to a

zero-crossing event by the flip-flop (where the output of Q only

changes at the next rising clock edge).

One effect of this is that the flip-flop can only shut off the

drive at rising clock edges, so depending on the phase of your

feedback, it can either shut the drive at n cycles or 0.5+n

cycles. This also means that the current can potentially grow

for about 1.5 half-cycles at worse case, so you need to be aware

of this and set your current limit conservatively.

Here's a back-of-the envelope example: Suppose my primary

current ring up is more-or-less linear and rings up at about

100A every half cycle. I want to make sure my IGBTs see at most

1000A, and this will happen in 5 full cycles. At the worse case,

it takes about 1.5 half cycles to trip the OCD, hence the OCD

should be set at around 850A or so. This will lead to turn off

after a peak current of either 900A or 1000A depending on CT

phase.

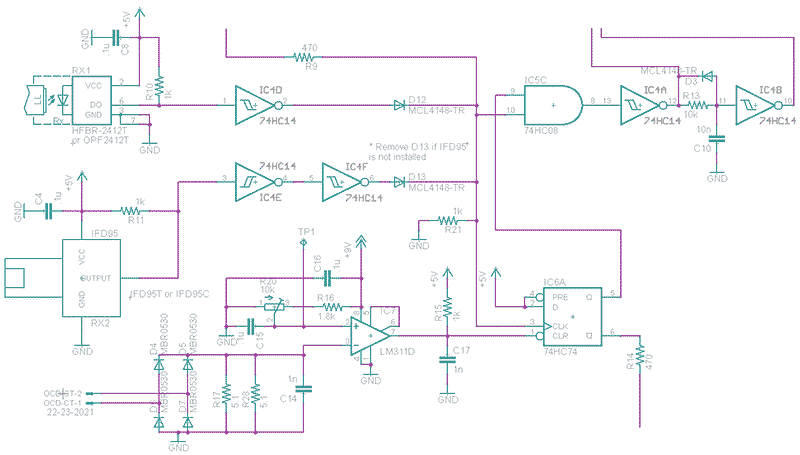

Interrupter input and Over-current Detection

For safety (physical isolation) and noise immunity, control

to the UD2.7 driver is via a 1-bit fiber optic transmission

system. UD2.7 uses

the dual inputs introduced in UD2.5, allowing the use of either ST

Fiber optic or Industrial Fiber plastic fiber optic receivers. These optic

lines are driven by an interrupter of your choice, (light on =

drive on). Because the ST fiber receiver is active low, the output is

inverted once via IC4D. The open collector output of the IF

receiver is cleaned up using two inverters IC4E and 4F. These

two inputs are then ORed together via D13 and D12.

Note that D13 should be removed if the IF receiver is not

installed, and only one of the optical receivers should be driven at any

one time. Notice that the IF-D95OC has a open collector output

and the IF-D95T is a push-pull TTL output. Since they are active

high (unlike the ST receiver which is active low), if these are

not installed, the input line will not be pulled low by the receiver

(due to R11 pulling it high), and the interrupter line will

appear to be constantly high. Hence D13 needs to be removed.

Now lets look at the Over-Current Detector circuit.

Similar to the FB circuit,

OCD feedback is obtained via a current transformer much like the

feedback transformer. The output is full-wave rectified via

D4-D7, and

loaded across R17 (5.1 Ohms). I usually try to wind my CT to get

about 1A across my load resistor, or about 5V across the burden

resistor.

This goes into the LM311 comparator, which compares this voltage

with a threshold voltage that is set by the multi-turn

potentiometer R20 and R16 (voltage diver).

The output of the LM311 feeds into the CLR' of another flip

flop IC6A, to ensure that an OCD trip is independent of phase-lead feedback.

This is ANDed together with the interrupter signal, and goes

through two inverters before going to IC6B, the other flip-flop.

An additional pad for a parallel resistor R28 is added on the

PCB (typically empty), which can be used in the primary currents

are very high and hence it would be convenient to add a parallel

resistor to lower the burden voltage across the CT, instead of

winding a higher-turns-count CT.

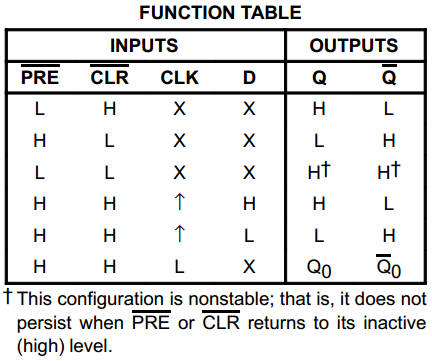

Here's the flip-flop function table (from TI's datasheet):

Now (looking at IC6B), before the OCD trip happens,

PRE' and CLR' are LOW and HIGH respectively, so irrespective of

CLK and D, output Q is HIGH, so our driver is running. So when

an OCD event happens, the output of AND (IC5C) goes to LOW,

hence PRE' of IC6B goes to HIGH a short while before CLR' goes

to LOW because the resistor-cap-diode network R13 and C10 sets a bit of

delay on the order of 100us before the 7414 hits its threshold

HIGH voltage. Therefore IC6B sees HIGH and HIGH on PRE' and

CLR'. Since D is pulled to LOW, on the next rising clock edge

from the feedback, Q is then asserted LOW. If a rising edge

doesn't occur for 100us for some reason, then with H, L on PRE'

and CLR', the drive is shut off anyway. This places a lower

bound of Tesla Coil operation at around 10kHz for ZCS-turn off.

Under-Voltage Lock-Out (UVLO)

UVLO is straightforward and originally suggested by Hydron from

the forums.

UVLO is an important feature and prevents under-driving of the

IGBT gates if the 24V rail should fall to some low voltage, which

could due to a power loss or a rail sag. Such an event could

also create problems with the logic, so we want to shut down our

drive in such an event. R29 and R30 (replaced by a potentiometer

in B revisions onwards) and form a voltage divider on

the 24V rail such that when it drops to below around 22V, it

will cross the 2.7V (or 4.5V depending on part) threshold of the UVLO IC. C34 is added for

noise immunity but can be omitted. For recovery, C25 sets the

time which is about 1 second before it resets, with 1uF. The

reset (RS) pin is an open drain output and is connected to the LM311

output. As such, it has the same effect as having an OCD event,

pulling P1 of the 74HC74 to 0V, and the drive is shut off at the

next current zero crossing and the OCD LED is turned on, until

the 24V rail recovers and the interrupter is next triggered.

Note that the above schematic is of the UD2.7A. The B revision

onwards includes an extra jumper for UVLO

enable/disable, as well as a potentiometer for adjusting the

UVLO set voltage (via Tap Point 2). For similar operation, set

the potentiometer R29 to be 33k (where TP2 =

3.0V). This voltage can be increased to add

more leeway.

Note that the maximum voltage the LM8365 can tolerate is

6.5V. By default, R29 (50k pot) comes set to half (25kR

resistance). This gives a safe voltage of around 3.8V by default

which should be adjusted. However, IF R29 is set to say 0R by

accident before soldering in, this can place a very high voltage

(>6.5V) to the LM8365 causing it to pop! Be

careful when installing R29! Thanks to Justin on 4hv for

pointing this out!

Soldering up the UD2.7

Soldering the UD2.7 should be quite straightforward. I recommend

soldering all the small SMD components before through hole

components. The power Mosfets may be tricky to solder and may

require higher temperature soldering iron to heat up the pads,

as do the voltage regulators on the other side.

Other things to take note are the Polarity of the small SOIC

chips. Also, D13 should be omitted if the black IF fiber optic

is not installed. C33 has larger solder pads for easy changing

of capacitor values. Finally, the right-most two mounting holes

are grounded, while the left-most two are isolated. 4-40

or M3 sized

screws are recommended for mounting the board / IF fiber

receiver.

Refer to the photos of the TOP and BOTTOM of the board above to

get a better idea of how the component placing should go. I

found it easier to solder everything SMD on the top side first

before soldering the bottom side, followed by through hole

components.

24VDC Input

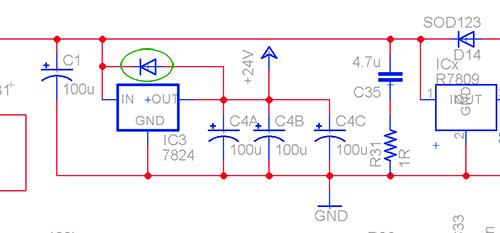

Errata for UD2.7A/B [Update: December

2014]

I found a a small error on the PCB (both Rev A and B w.r.t. the

24VDC input) thanks to Daniel, but with a simple fix so no

worries! This only applies if you are using 24VDC input.

This

error has been fixed in the UD2.7C.

Problem: This happens when the 24VDC jack is

used instead of the AC input of only the UD2.7A and B. The 24VDC jack goes directly to

the 24V rail. However, the 9V switching regulator's input is not

connected to the 24V rail but rather the rectified AC rail. I

originally wired it this way to reduce added load on the 24V

regulator, since the 9V switching regulator accepts up to 34V

input. But it looks like I got ahead of myself!

You would think that this meant that the 9V and 5V rails would

not be powered, but it turns out that inside the 24V regulator,

there is a diode in series with about 28k from the output to the

input, hence allowing the regulator to 'conduct backwards'. This

also explains why the board still checked out ok on the voltage

rails, probably helped by the generous amount of logic bus

capacitance and the fact that the logic doesn't draw too much

power. Even without any fix though, the board seems to work fine

powering coils hence explaining why I didn't see the error at

first. However, probably a good idea to fix the problem.

Fix: If you're using AC input, there is no

problem. If you are using DC input there are two ways of fixing

it. First, you can supply 26.5VDC into the AC jack instead - the

diode bridge drops about 0.5V and the 7824 drops about 2V for

24V on the 24V rail. Most 24VDC power supplies usually have

small adjust pot.

Second way: If you're using the DC input, the problem can be

solved by a simple fix - simply solder on a diode from the

output to the input of the 7824 regulator (i.e. classic reverse

protection diode). So when the 24V rail is powered via DC input,

current flows across the regulator to the input of the 9V

regulator. With this fix, even when powered via AC, the diode is

simply acting as the classic reverse protection diode. The diode

I used for D14 (GSD2004W-E3-08 - just order an extra one when

you're in Mouser) as a reverse protection diode across the 9V

switching regulator can be used for the 24V regulator, or any

other general purpose diode will be fine. This can be soldered

directly across the legs of the 7824 regulator and fits

perfectly. Make sure the diode is from the output to the input.

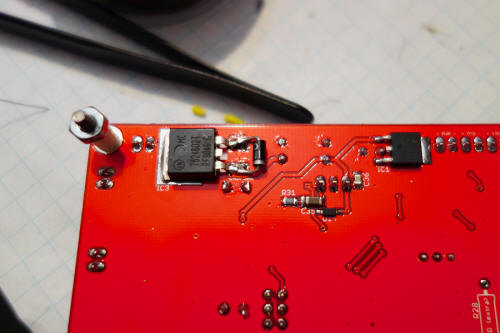

Above is a fix with a standard 1N4001 diode across the 24V

regulator, on the V2.7A board. In the new V2.7 Rev C, I have

fixed this error and the 9V regulator input is now powered from

the 24V rail.

The UD2.7 is best tested with a current limited adjustable power

supply at 24VDC into the DC input jack. Upon turning it on, the

on-board SMD power indicator LED should turn on. At this point,

check the three power rails to ensure that you have 24V, 9V and

5V. None of the components should get warm at all. Next, connect

your fiber optic cable to the fiber optic interrupter of your

choice. Attach a LED on the Signal LED jack (the middle pins of

the 6-pin LED jack). Check that when the interrupter is running,

the LED should light up correspondingly. This verifies your

optical receiver is working. Take note that D13 must be removed

if the IF fiber receiver is NOT installed.

A quick way to verify that the board is working is using a

signal generator running at your desired frequency to simulate

feedback. Set your frequency / signal generator as a sine wave

of around 5V amplitude at your desired frequency (e.g. 100kHz).

Connect this to the input of the Feedback jack (not the OCD

jack). Now connect the ground of your oscilloscope to the ground

of the board and scope the outputs of the gate drive, and turn

on your interrupter.

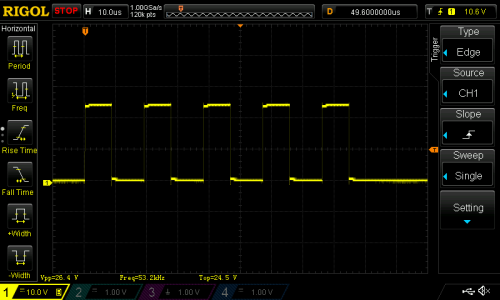

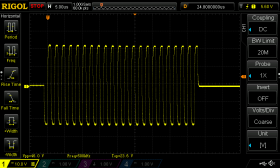

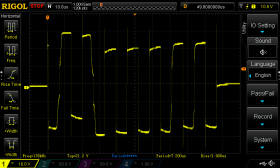

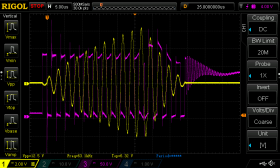

You should see the above 50% duty cycle square wave at +24V at

the input frequency of your signal generator. The example above

shows one of the GDT outputs running at about 53kHz at a pulse width of about 85us.

Because the UD2.7 implements a flip-flop for zero-crossing

turn-off, the gate drive should

always end at a transition point. The amplitude should be

single-sided 24VDC with a 50% duty cycle. If you see this for

all four GDT output pins, your driver is working as expected.

With NO GDT connected, the driver should be quiet.

The driver creates a +- 24V output for the gate drive

transformer. To verify this, I made a very quick lash-up

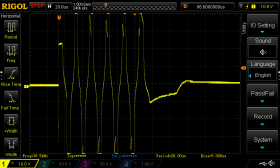

transformer for test. Note that this is NOT an ideal GDT -

please wind a better one for your own DRSSTC (these scope shots

show too low primary inductance - can be solved by adding

more turns, but this was just a quick lash-up to show the driver

working). Above shows the secondary of the GDT across a small

resistor at 50kHz and 500khz. The photo on the rightmost shows a

situation caused by an incorrect C33.

Note that if you have no input signal in your FB jacks, the

driver will not see any feedback, causing the drive to lock up.

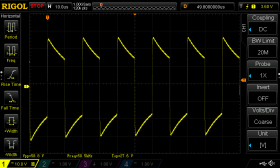

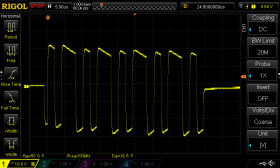

Here's a scope shot of a GDT output with a feedback input signal

(left). But if you have a GDT attached with no

signal generator input on the feedback, this will make a signal

on the output of the GDT look like the above (right - where the

driver doesn't know what to do), and will cause quite a loud

audible buzz from the GDT with this associated output per pulse.

This sound should diminish greatly with a feedback input signal.

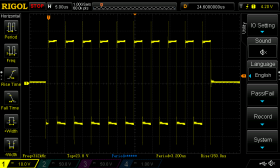

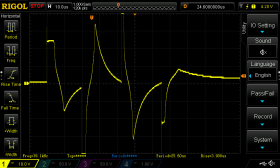

At low frequencies, you might notice your GDT saturating. This

will cause very unstable, ugly switching, and the result will

also be a very erratic and audible buzz on your GDT, as shown in

the three scope shots above. Fix this by making a better

GDT.

You should adjust C33 to suit your

needs. For example, the use of 2.2nF for C33 limits the maximum

frequency to at most ~250khz, resulting in a bad drive (right most

image). If you see this, change C33 to a smaller value (220pF to

1nF), or reduce your frequency. Note that the output is +-24V.

At this point, your driver should be ready for basic operation.

I have tested the UD2.7 all the way from 12kHz to 1.04MHz

(whereas 220pF seems to be good from ~150khz upwards). 1nF

should be good for most applications.

It is also a good idea to test the under-voltage

lockout and OCD. To test the UVLO, continue scoping the output

with the interrupter on, and slowly turn down the voltage from

your adjustable DC power supply. Depending on the tolerances of

your voltage divider on the UVLO, the output of the driver

should stop once it drops below around 22V and the OCD light

will remain on. The minimum lock-out will be about one second

or so, before coming on again when the 24V rail recovers (can be changed by adjusting the

value of the 1uF capacitor). OCD is tested the same way by

increasing an input sine-wave voltage until the set level. At

this point, the OCD light should turn on and the output will

stop.

Phase lead can be adjusted by choosing an appropriate adjustable

inductor and carefully adjusting it to suit your Tesla Coil.

This is the way I usually tune my coils for phase lead. First

determine the general operating frequency of your DRSSTC. In the

example shown in the scope shots above, I am running my DRSSTC

at about 380kHz. Run the DRSSTC without the secondary coil in

place. I usually use a metal object as a load in the middle of

the primary coil. This could be as simple as a metal pan with

some water inside, or a block of steel.

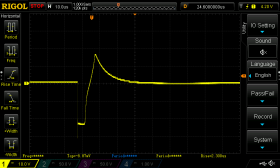

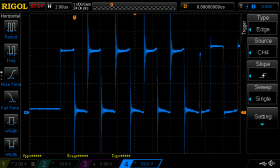

Next, power your DRSSTC as usual, but with a lower bus voltage

if desired. Note that to take scope measurements, you should

isolate your entire drive circuit! This is very important. In

the example above, I am running my bridge at about 170V bus. The

blue trace shows the Collector-Emitter voltage of one side of

the bridge showing the output of the bridge with no

phase lead (this can be set by the jumper beside the

tunable inductor). Note the huge spikes during the transitions

greater than 100V! These can kill IGBTs since IGBTs are

extremely sensitive to over-voltage, and it is very difficult to

get rid of these spikes even with a low inductance layout due to

the intrinsic component inductance which cannot be removed.

I then tried a few different inductors (see quick notes above

for which values to use), and adjusted the phase lead while

looking at the scope. As you move closer to the sweet spot, you

will notice the spikes dropping in amplitude all the way until

they.. suddenly disappear. This is the sweet spot and your coil

is tuned appropriately.

It will be impossible to completely eliminate all switching

spikes. What I do is to ring up the primary (by adjusting the

pulse width on my interrupter) until it hits a current I plan to

run the coil at. In scope shot 2, you can see the primary

current (yellow) versus the bridge output (pink) with

phase lead. At this point, the current ramps up to

about 130A. I have also adjusted the phase lead such that the

spikes are the smallest at the last few cycles when the current

is the highest. The third scope shot shows a close up of shot 2,

showing beautiful, clean switching.

This point is achieved at a type of switching known as

zero voltage switching (ZVS). In this case, the IGBTs

are switching not at exactly at zero current, but at zero

voltage. The best way to visualize this is to overlay the

gate-emitter and collector-emitter voltage of one of the IGBTs

during operation. What you want to see is when the opposing

IGBT turns OFF, the bridge voltage begins to fall to 0 and

invert. Note that IGBTs really turn into a conductive state as

the gate voltage reaches a plateau around 10V. So when scoping

the gate voltage, you will see it rise up quite fast, plateau at

~10V, before shooting up to 24V of the gate drive. The trick is

to adjust phase lead such that just when the bridge voltage

transitions at 0V, the gate is at this plateau, and all ringing

should disappear. For more details, scope shots and tips on

choosing a suitable gate resistor, see my

DRSSTC 3 page where I walk through this procedure in detail.

In summary - set your bridge for ZVS which will lead to the

smallest spikes. Aim for the cleanest transitions at the highest

current. I found that setting for a clean transition at about 20

to 25% of expected peak current usually leads to good results.

Setting OCD on the UD2.7 is as simple as adjusting the large

variable resistor R20, and measuring the

voltage at tap point 1 TP1.

For example, lets say we are building a DRSSTC where we do not

want the IGBTs to see more than 700A primary current. Note that

by design, the UD2.7 only switches the transistors OFF during a

zero current crossing via a flip-flop (this is to prevent

switching off the IGBTs when huge currents are flowing). This

means that even after the OCD trips (say while the current is

ramping up during a quarter RF cycle), the current can continue

rising to higher than the OCD trip point for up to 1.5 half

cycles before it goes back

down. Therefore, we might want to set our OCD point to 600A or

so.

Next, count the number of turns on your primary current

transformer. Lets say we have a 625:1 current transformer made

by cascading two 25:1 transformers. Therefore if 650A is flowing

in the primary, we will see 1.04A in the OCD CT. This current is

full wave rectified and flows across the burden resistor R17

(5.1 ohms). By ohms law, at maximum current, we will see 5.1 x

1.04 = 5.304V across R17. Therefore, adjust R20 until TP1 shows

about 5.3V and you're all set!

Note that for larger coils running at say 2000A with a 1000:1

current transformer, another burden resistor can be placed

along-side R17 (R28), to reduce the burden resistance. Note that

the comparator LM311 has limits at its 9V VCC voltage (minus

some since comparators are not accurate near the rails), so make

sure the trip voltage is less than say 8V or so.

The UD2.7A has been tested to work extremely well in QCW DRSSTC

operation. See my QCW 1 page to see it in

action. However, it was certainly not designed with QCW

operation and therefore you should understand its limitations

which is out of scope for this page and obvious to the skilled

coiler.

Some modifications should be made to the board for proper

operation. This mostly relates to the long drive required by QCW

operation, where the driver has to switch IGBTs for several

thousands of cycles instead of around 10 or so in normal DRSSTC

operation. The result is that the 24V voltage rail may drop to a

dangerously low level due to insufficient 24V rail capacitance

and / or insufficient logic power from say a 20VAC transformer.

Fortunately, the UD2.7A has an under-voltage lock-out, which

will prevent your IGBTs from desaturating and blowing up when

the 24V rail drops too low. However, it might

limit the pulse width you can drive your IGBTs. In addition,

QCWs usually operate at around 300 to 400kHz, and correct

selection of C33 is required.

-

I found using C33 = 220pF works great for high

frequency operation. Solder 220pF

on C33 for 300 - 400+kHz operation.

-

Add extra bus capacitance on the 24V rail. You can

simply replace C4A and C4B with higher capacitance electrolytic

capacitors, or tack on a few extra outside the board. The default

values for C4A/B at 8mm diameter 35VDC 220uF capacitors. I found

adding an extra 1000-5600uF capacitor works great depending on your

application. There is space on the

UD2.7B/C board just for purposes like this (C4C).

-

Iron transformers are usually unable to supply

enough power to the board for QCW operation. Another alternative

instead of adding extra capacitance on board that works great is to

use a 24V

switch mode power supply as a power source (instead of a 20V

transformer). These supplies usually

have an output filter capacitor as well which gives extra bus

capacitance.

You may find that the 24V rail voltage can still drop to 22V,

triggering the UVLO. Another way to fix this is to simply lower

the UVLO trip voltage by lowering the resistance of R29. This can

be easily done by kludging another SMD resistor (say several

hundred kOhm) over R29 in parallel with the existing 33k

resistor. The UVLO IC can be left-out all together, but I do not

recommend this. Your IGBTs will explode if they desaturate with

several hundred amps through them. UD2.7 Rev B and Rev C replaces

R29 with a 50k potentiometer for easy adjusting of the UVLO voltage

threshold.

Back to main page

(c) Gao Guangyan 2016 - 2025

Contact: loneoceans [at] gmail [dot] com |